custom made aluminium ,zinc and magnesium alloy die casting

Basic Info

Model No.: kenos-4002

Product Description

| Product name | Custom made aluminium ,zinc and magnesium Alloy Die Casting | |||||

| Briefly Description | 1. zinc and magnesium alloy are the main product material | |||||

| 2.10 year's experience in Die Casting field | ||||||

| 3.OEM and ODM service offered | ||||||

| 4. One stop service from Die Cast mould making to product casting | ||||||

| Mold type | Die Casting Mould | Usually packaging | Paper of Box | |||

| Manufacturer | Kenos Hardware Technology | Orginal place | Dongguan China | |||

| Supply capability | 50000PCS/WEEK | Terms of transport | by ship or express | |||

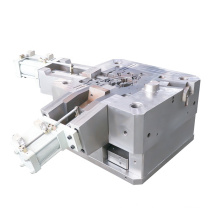

| About Our Mould : | ||||||

| 1)Mold type: die casting mold as customer's drawing or sample | ||||||

| 2)Mold tolerance:generally wirthin +/-0.03mm | ||||||

| 3)Mold size:either small or big are available according to product,generally length from 100mm to 1 meter | ||||||

| 4)Mold making process:milling,grinding,wire cutting,CNC,EDM,etc | ||||||

| 5)Mold making equipment: | ||||||

| 1. eight sets of milling machine | ||||||

| 2.three sets of grinder | ||||||

| 3. two sets of wire cutting machine | ||||||

| 4. one set of CNC machine | ||||||

| 5. five sets of EDM machine | ||||||

| 6)Mould life:Over 1000,000 shots,lifetime free for maintaining the mould | ||||||

| 7)Drawing type:PDF,DWG,IGS,STP,STEP,PRT are all acceptable | ||||||

| About Our Product: | ||||||

| 1)material type:mainly magnesium and zinc alloy with SGS certification | ||||||

| 2)Product tolerance:according to customer's requirement and decided by the mold | ||||||

| 3)Main products:die casting parts,die casting accessories,die casting components, including phone shell,automotive parts,compouter parts,PC parts,bicycle parts,camera parts,housing,parts,gears,diy tools,optical components,engine components,pump components,furniture,fittings,etc | ||||||

| 4)Related industry:computer,cellphone,communication,LED,automotive,Camera,optical,etc | ||||||

| 5)Main process: Die casting,deburring,hole drilling,tapping,polishing,plating,inspecting,packaging | ||||||

| 6)Product making equipment: | ||||||

| 1. 3 sets of magnesium alloy die casting machine (hot chamber) | ||||||

| 2. 4 sets of zinc alloy die casting machine | ||||||

| 3. 4 sets of aluminum alloy die casting machine | ||||||

| 4. 34 sets of punch press | ||||||

| 5. 4 sets of hole-punching machine | ||||||

| 6. 15 sets of tapping machine | ||||||

| 7. 2 sets of CNC machine | ||||||

| 8. 10 sets of lasering welding machine | ||||||

| 7)surface finish:Zinc plating,Chrome plating,Trivalent chrome plating,Powder coating,Painting,E-Coating.Phosphating,Anodizing,etc | ||||||

| Our main advantage: | ||||||

| 1)specialize in magnesium and Zinc Die Casting for 10 years | ||||||

| 2)Green products with many international certification | ||||||

| 3)Good quality products with competitive price | ||||||

| 4)Best after-sale service | ||||||

| 5)One stop service to solve all of your problems | ||||||

| 6)Always on service for you during your working time | ||||||

| 7)Quotation will be sent within 24 hours any time | ||||||

| 8)Always on service for you during your working time | ||||||

| 9)Samples could be provided for customer's trail and test.Once not meet customer's need, | ||||||

| we will modisfy the mold until customer's satisfactory | ||||||

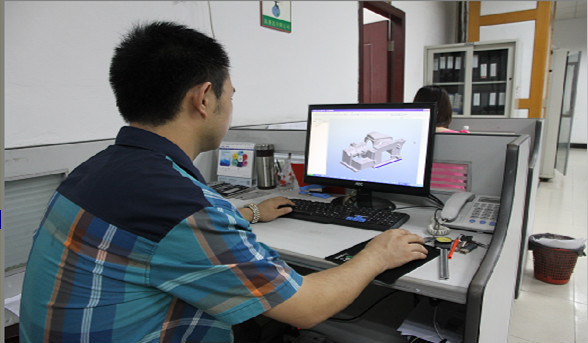

Mould Design

Mould Design  Milling processing

Milling processing  CNC Machining

CNC Machining  EDM wire cutting

EDM wire cutting  EDM spark erosion

EDM spark erosion  Mold inspection

Mold inspection  Mould Room Product die casting process:

Mould Room Product die casting process:  Magnesium Die Casting

Magnesium Die Casting  Degating

Degating  Deburring

Deburring  Drilling and tapping

Drilling and tapping  CNC machining Product Inspection:

CNC machining Product Inspection:  Inspection room 1

Inspection room 1 Inspection room 2 Package:

Inspection room 2 Package:  Contact us if you need more details on Aluminium Zinc Magnesium Alloy Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Alloy Die Casting、Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Aluminium Zinc Magnesium Alloy Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Alloy Die Casting、Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Die Casting Mould

Premium Related Products

Other Products

Hot Products

Stainless Steel Investment Casting Housing BoxZinc HousingBending HousingDuctile Iron Casting Parts-Green Sand CastingFilter Cap-CNC Machining From Casting Ss316, Lost Wax CastingAuto Lock Body-Stainless Steel Ss316 Lost Wax CastingSS Investment Casting (AISI304)Forging Parts for Railway Swivel Front BarDuctile Iron Casting of Hub Made From Lost Foam CastingPipe Fittings Aluminum Gravity CastingEspresso Coffee Machine Housing Made by Die Casting with Excellent FinishManufacturing high precision zamak die casting Samsung phone caseHigh pressure aluminum die casting communication componentscustom made aluminium ,zinc and magnesium alloy die castingPrecision Magneisum Die casting Phone housingsPrecision Magnesium die casting mould making